Top Of The Line Products

AMWI’s current suite of inspection scanners and equipment, shown below, have all been tested in the laboratory and used in actual field scanning applications. We continuously evolve and improve our scanning devices to meet operator and customer needs and expectations. At AMWI, we work with ASME, ASTM, ASNT API, ISO, and other standards agencies to stay abreast of the latest inspection needs and so we are always adding new scanners to meet these new challenges.

If you have a special inspection requirement, please let us know and we will be happy to work with you to develop the right tool for the job. Check this page frequently for new additions to our fleet of equipment.

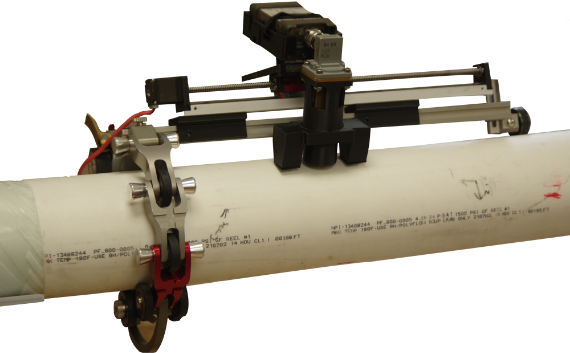

Pipe Scanner

The AMWI pipe scanner is a semi-automated pipe scanner based on the Jireh chain scanner. The system uses a stepper motor and controller and an encoded axis so you get fully encoded scanning capability. A single pipe scanner can inspect 3” diameter pipe up to 24” diameter pipe and as long as 18” in the axial direction. Multiple scanners can be assembled to scan pipes up to 60” in diameter. The system is provided with a remote umbilical push button control for the scan and reset features, so the operator can be remote from the computer.

The standard system uses the 6GHz to 14GHz microwave system, or an optional 6Ghz to 18GHz system can be purchased. The system is simple to use and set-up and uses the same microwave system and antennas as well as data acquisition software and data analysis software as the MAPS so they are fully compatible with each other. The AMWI pipe scanner system requires 120V A/C or can be fully battery operated (optional).

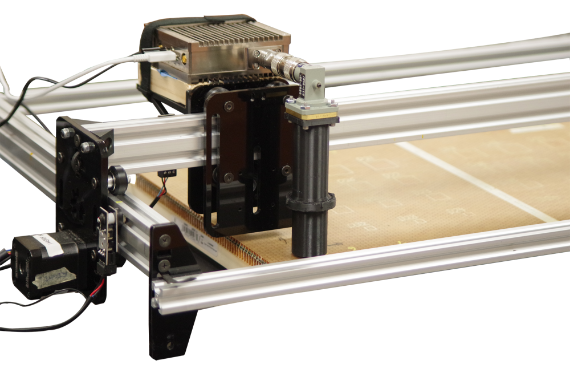

Table Top Scanner

The AMWI Table scanner is an X-Y stepper motor system to provide fully encoded scans on flat samples. The system comes standard with the 6GHz to 18GHz AMWI microwave system and antenna. The scanning speed is upwards of 25mm/sec at a nominal 201 or 401 data point setting. The data acquisition software is based on the same software that the other AMWI systems employ. The X-Y frame can be purchased in various sizes and can be mounted on a specialized table, or it can be used on an existing table top.

The multi-frequency microwave system and antenna are provided with a specialized suspension system to allow for various thickness samples to be inspected.

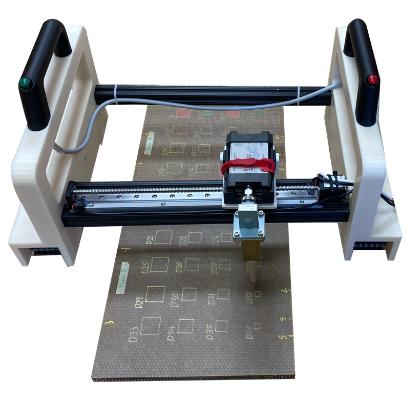

Motorized Axis Portable Scanner

The AMWI MAPS system is a lightweight, portable scanning system that can be used for a variety of scanning applications. The system can be used on any large, circular or flat components. The system is modular in design with handles and pushbuttons so the operator has full remote control of the system during operation. With the optional onboard computer, remote screen, and battery power, the system is completely portable and ideal for scanning difficult-to-access locations, such as up-tower inspections of wind turbine blades.

The unique modular system allows for simple reconfiguration from a horizontal scan vertical index (wheels vertical) orientation for flat surfaces such as boat hulls to a vertical scan horizontal index (wheels horizontal) orientation for large round surfaces like storage tanks or vessels. The handles are also re-oriented for ease of operation in either configuration.

When coupled with the AMWI DAS and audio positioning system, the AMWI MAPS is a unique scanning platform that can inspect a wide variety of components.

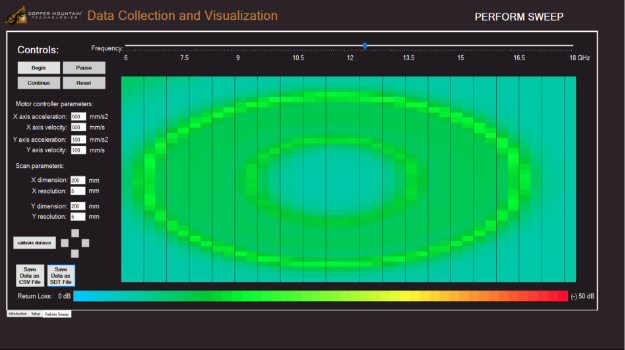

Data Acquisition Software

The AMWI DAS was developed specifically for use with the AMWI Multi Frequency microwave inspection systems and the AMWI scanners. There is a separate DAS for the Table Top Scanner and one for the pipe scanner/MAPS. The AMWI DAS was designed to make it easy for the operator to setup and use to ensure repeatable scan data. The software has built-in calibration windows for the multi-frequency microwave system as well as the stepper motor and encoded axes that make it easy to calibrate the AMWI microwave systems prior to use.

The DAS for the pipe scanner/MAPS has a unique built-in audio function to alert the operators as they approach the encoder distance setting. This allows the operator to accurately position the manual system remotely from the computer screen.

The DAS was designed to optimize the data collection speed and positional accuracy to ensure proper data collection for input to the AMWI Data Analysis Package. As an added convenience, the DAS has an option to save data in a CSV file format for post-processing outside of the AMWI Data Analysis Package if desired.

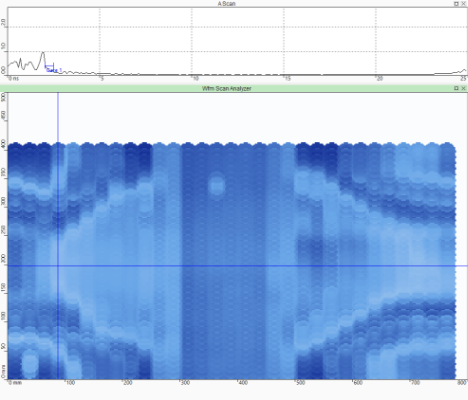

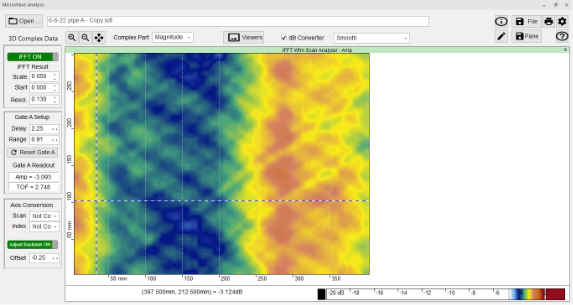

Microwave Analysis Software

The heart of the AMWI data analysis system is the Microwave Data Analysis Package, or DAP. The DAP is based on Utex Inspectionware and has been specifically designed to accommodate the AMWI multi-frequency data set. The analysis package allows for display in multiple color and gray scale palettes in multiple modes. The analysis page is laid out in A scan, B horizontal, C scan and 2 data lines (X and Y direction). The Level II can view the Real, Imaginary, Magnitude, or Phase data in either a signal power (dB) mode or raw signal mode.

Additionally, because of the multi-frequency aspect of the AMWI system, the data at a specific frequency range can be viewed . This is helpful to identify different signal response versus frequency for that material. The entire range of frequencies is used to convert the signal from frequency based to time based by simply moving a toggle. This now allows the images to be created over a range of depths in the part. This can be used to determine remaining wall thickness of a component, location of flaw within the depth of the part, or inspection of a specific depth location in a series of similar components, such as the plane of fusion in a HDPE Elecro-fusion.

The AMWI DAP includes sizing and annotation options and easy image saving for ease of reporting.

SAFT Analysis

The latest addition to the AMWI Data Analysis Package (DAP) is the Synthetic Aperture Radar focusing add-on. This additional analytical technique has been provided to allow for a more precise depth of flaw definition.

The SAR function allows for precise focusing of the microwave beam in the depth of the part, which provides better resolution of flaw size and location. This part of the DAP is still in Beta testing but should be ready for deployment in the next few months.